No. 22 Maowu North Rd., Tangjiahui Village, Jiangshan, Ningbo, China.

Ningbo Minde Technology Co., Ltd.

NINGBO JDA IMP & EXP CO., LTD.

- Products

- Profile Fastening Accessories

- Profile Connecting Systems

- Alu. Angle Connectors / Alu. Corner Brackets

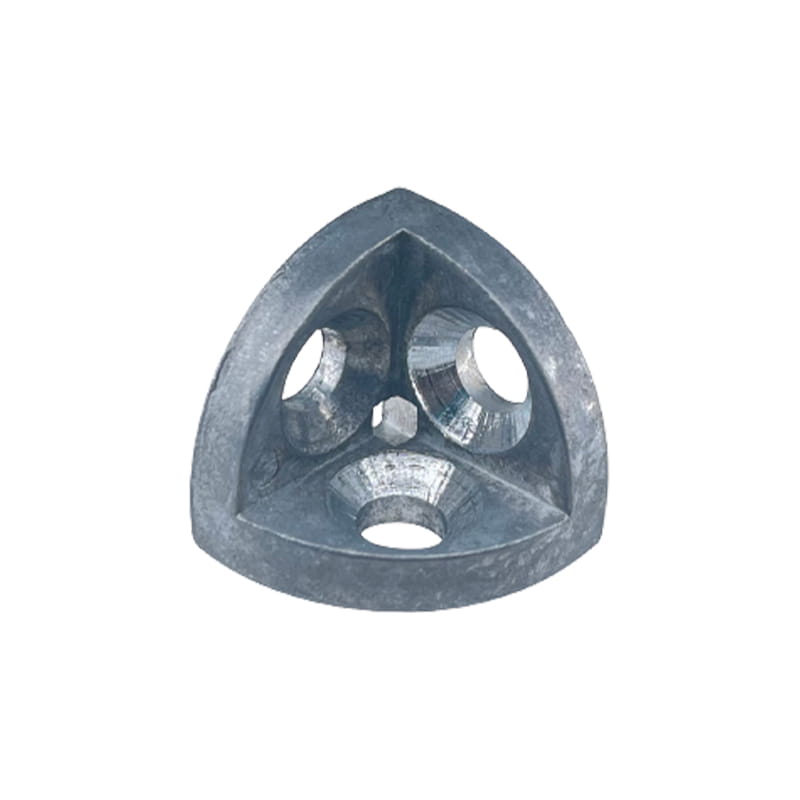

- Zinc Casting Gussets / Zinc Casting Corner Brackets

- Steel Angle Connectors / Steel Corner Brackets

- Inside Corner Brackets / Al. Connection Angles

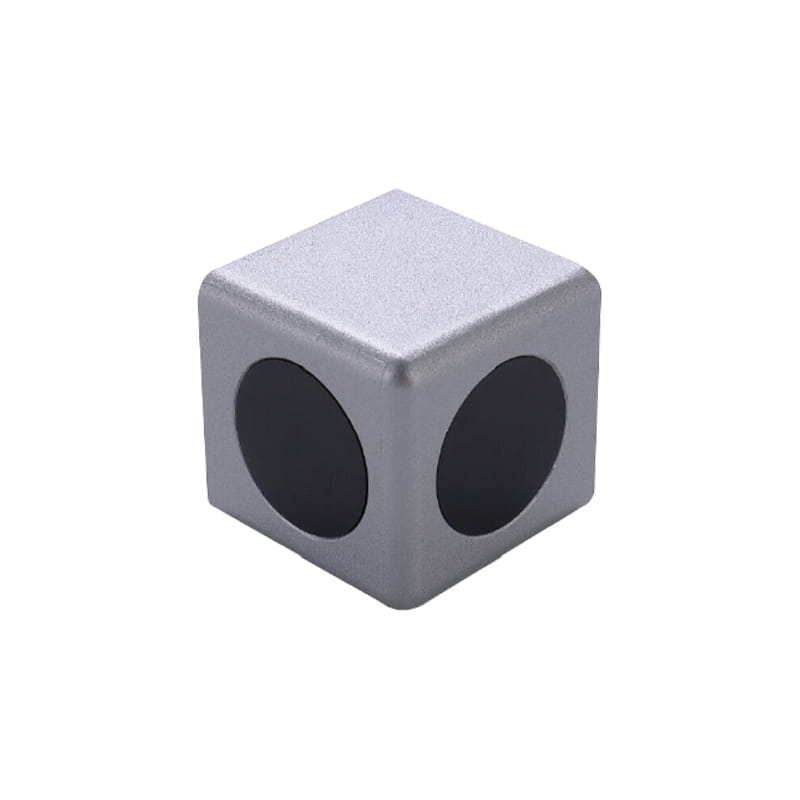

- Profile 3-way Cubic Connectors

- 2 Profile ways Cubic Connectors

- 3-way Connection Angles / 3D Corner Brackets

- Profile Bolt Connectors

- Profile Central Connectors / Quick Connectors

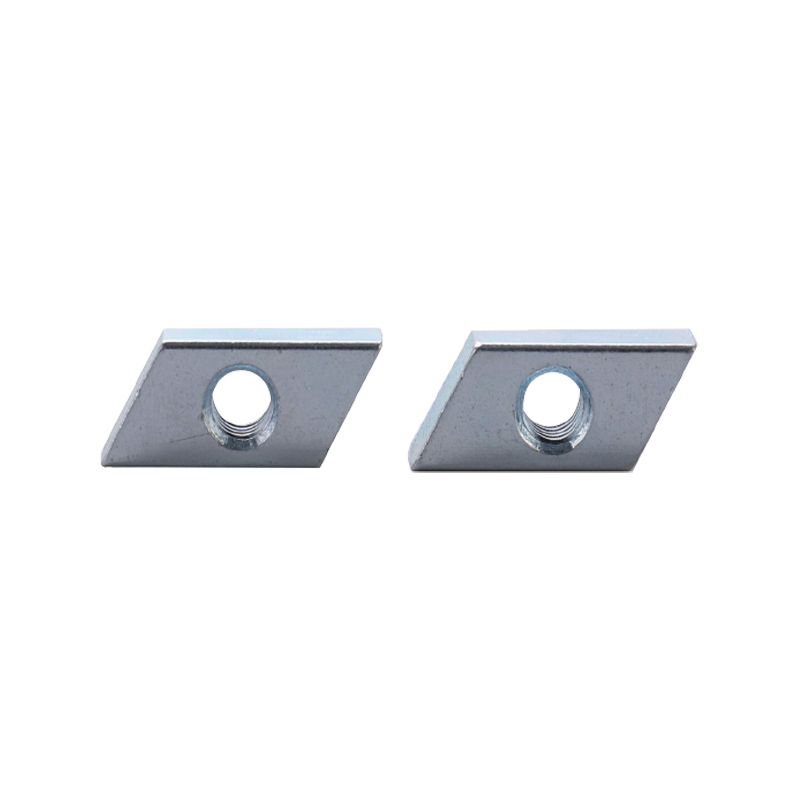

- Profile Connection Plates

- Profile Automatic Connectors

- Profile Central Screws / Profile Central Bolts

- Profile Plate Connectors

- Profile Anchor Fasteners

- T Slot Profile Inner Connector

- Profile End Fasteners

- Profile Pivot Joints

- Profile Connector 90°

- 3-Way End Corner Connector

- Profile Turning Plates

- Profile slide hooks

- Profile Panels & Doors Fasteners

- T Slot Floor Elements

- T Slot Covers

- T Slot Profile End Caps

- Cable Tie Mounting Blocks

- Solar Mounting Components

- Customized Machinery Components

- Profile Sliders & Rollers

- Technology

- Applications

- News

- Company

- Sustainability

- Contact